On May 15, 2020, Professor Zhang Xu's team at the School of Mechanics published a paper online entitled "Cyclic plasticity of an interstitial high-entropy alloy: Experiments, crystal plasticity modeling, and simulations" in the top journal of Journal of the Mechanics and Physics of Solids, presenting a birthday gift to Southwest Jiaotong University on its 124th anniversary.

In recent years, the emergence of high entropy alloy (HEA), also known as multi-principal alloy, has broken the bonds imposed by the traditional design concept of making alloy with only 1 to 2 major elements, and initiated another round of the improvement of alloy properties. Fe49.5Mn30Co10Cr10C0.5 (at. %) is a new kind of high entropy alloy (hereinafter referred to as iHEA) developed by adding traces of interstitial atom C in metastable dual-phase high entropy alloy Fe50Mn30Co10Cr10 (at. %). After grain refinement, this HEA can form a structure similar to that of single-phase FCC, and various reinforcement and plastic deformation mechanisms involved endow the iHEA with sound strength-toughness matching.

Materials are often subjected to cyclic load in their life of service, and their low cycle fatigue life is greatly affected by the ratcheting behavior resulting from continuous accumulation of cyclic plasticity under the action of asymmetric stress load with non-zero mean stress. At present, plenty of macro and micro experimental studies have been performed on the single tensile deformation behaviors of iHEA, but no experimental study and mechanism analysis has been done on the cyclic plasticity behaviors, which to some extent hinders the evaluation of the alloy’s service capacity and engineering application.

Professor Kang Guozheng’s team at the School of Mechanics and Engineering (SWJTU) collaborated with German Max Planck Institute for Iron Research in testing cyclic deformation for single-phase iHEA, analyzed the microstructure characteristics of the deformed samples, and developed a crystal plastic constitutive model that can reasonably describe the ratcheting behaviors of high entropy alloy based on macro mechanical response and microstructure evolution. On May 15, 2020, relevant research results were published online in Journal of the Mechanics and Physics of Solid, the top one in the field. The paper’s corresponding author is Professor Zhang Xu, the first author is PhD student Lu Xiaochong, and the collaborators include Professor Kang Guozheng, Professor Kan Qianhua, Professor Li Zhiming, Associate Professor Yu Chao, and PhD student Zhao Jianfeng.

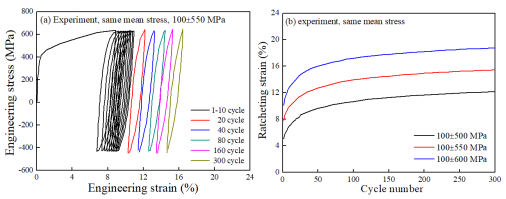

With the cyclic deformation tests under asymmetric stress control, this study obtained for the first time the cyclic stress strain curve and ratcheting strain evolution curve of iHEA. Under the cyclic load of different stress amplitudes, iHEA exhibited ratcheting characteristics identical to those of traditional alloy steel (304, 316L stainless steel, etc.). But at similar stress levels, iHEA has a lower saturated ratcheting strain rate than 316L stainless steel, indicating that iHEA has a stronger cyclic hardening effect and the ability to resist plastic accumulation.

Figure 1 iHEA’s stress-strain curve and ratcheting strain evolution curve under cyclic deformation.

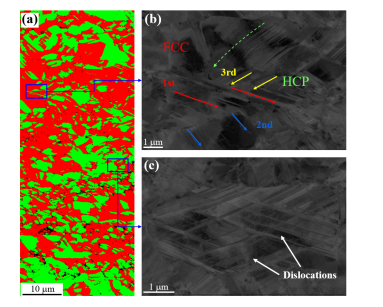

The researchers adopted micro characterization methods such as EBSD and ECCI and found that iHEA's cyclic hardening ability stems from the evolution of its special microstructure. Previous studies have shown that iHEA has three plastic deformation mechanisms: dislocation slip, deformation twins and martensite transformation. Compared with the single tensile deformation, a grid-shaped microstructure composed of multiple twins and martensite plates is generated inside the iHEA under cyclic loading, and the average volume fraction of martensite reaches 50%. In the case of single tensile, the volume fraction of martensite at the fracture with a local strain of 90% is only 36.7%. The rich internal interfaces, especially the appearance of grid-shaped microstructure, effectively shortens the mean free path of mobile dislocations and improves iHEA’s cyclic hardening ability.

Figure 2 iHEA's EBSD and ECCI characterization diagram.

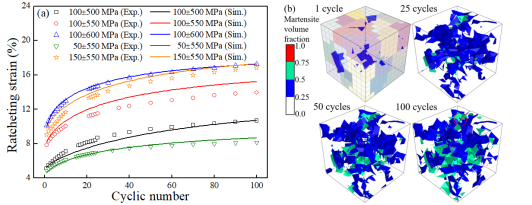

Based on the results of macro testing and micro characterization and related analysis, the crystal plastic constitutive model involving micro physical mechanism is further developed to describe the ratcheting behaviors of iHEA. In this model, isotropic hardening and kinematic hardening are respectively provided by tree dislocation strengthening and back stress while both are affected by the mean free path of the dislocation, or in other words, they are indirectly modified by plastic mechanisms such as twinning and martensite transformation. The model is realized by transplanting the finite element numerical value on DAMASK, a material simulation platform developed by the Max Planck Institute for Iron Research. The simulation results reveal that the model can better describe the evolution of ratcheting strain under different working conditions. The analysis on evolution of dislocation density, twinning and martensite volume fractions further manifests that the external load affects the hardening behavior of the materials via altering the evolution rate of the microstructure, thereby impacting the macroscopic deformation response of the materials. Furthermore, the results also demonstrate that the martensite is distributed very unevenly inside the microstructure as a result of the anisotropy of the polycrystalline materials, which is similar to the microstructure characterization.

Figure 3 Results of CPFEM.

Professor Zhang Xu’s "Multi-scale Mechanics of Materials" research group, affiliated to Professor Kang Guozheng’s "Material Constitutive Relations and Fatigue Fracture" research team, has published several papers in top journals such as Journal of the Mechanics and Physics of Solids, International Journal of Plasticity, and Acta Materialia.

Paper link:

https://doi.org/10.1016/j.jmps.2020.103971

He Songlin Granted the Best Paper Award at IEEE IPCCC 2024

He Songlin Granted the Best Paper Award at IEEE IPCCC 2024

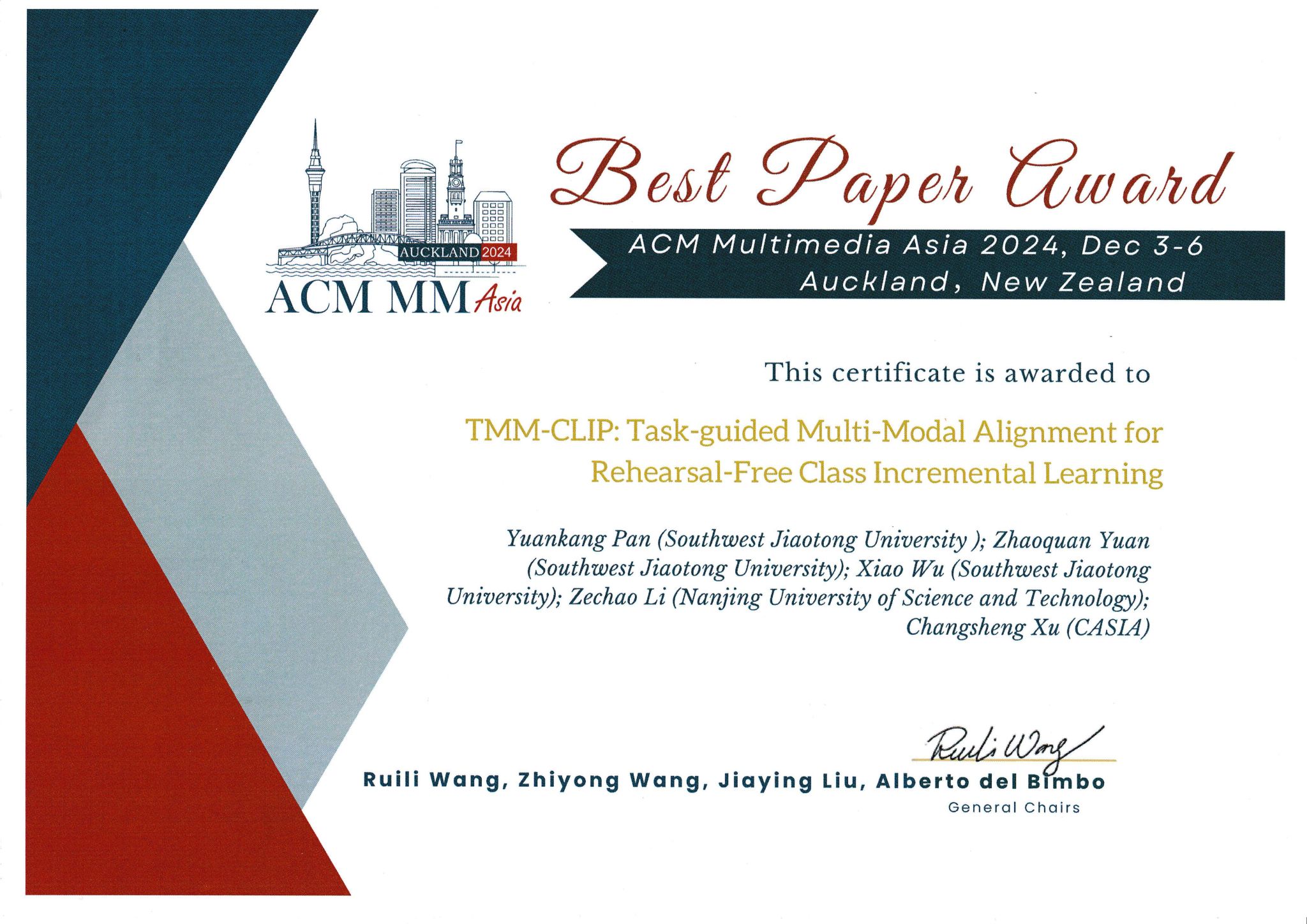

Prof. Wu's Team Bestowed Best Paper Award at ACM Multimedia Asia 2024

Prof. Wu's Team Bestowed Best Paper Award at ACM Multimedia Asia 2024

Alumnus Xi Yue Graced the Cover of 2024 Forbes 30 Under 30 China List

Alumnus Xi Yue Graced the Cover of 2024 Forbes 30 Under 30 China List

The 15th Asia-Pacific Symposium on Engineering Plasticity and its Applications

The 15th Asia-Pacific Symposium on Engineering Plasticity and its Applications

General Education Course on “Frontiers in AI Applications: Methods, Thinking, and Ethics”

General Education Course on “Frontiers in AI Applications: Methods, Thinking, and Ethics”